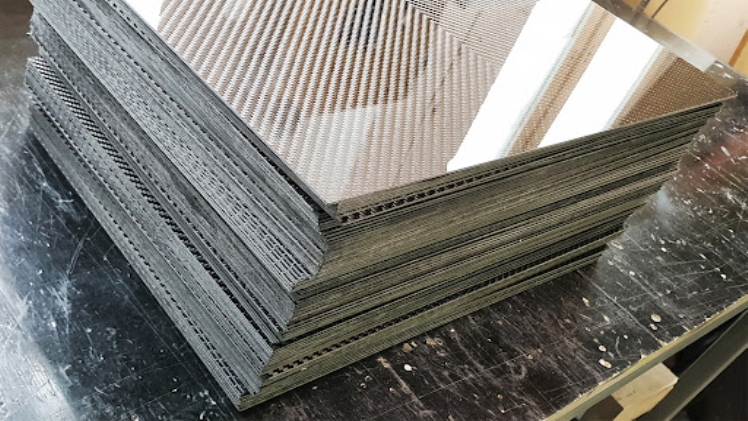

Carbon fiber is made from a variety of raw materials including polyacrylonitrile (PAN), rayon, and pitch. The production process involves synthesis of the raw material into a form that can be processed into yarn/filament, followed by weaving, braiding, or layering into a composite structure.

One of the challenges in working with carbon fiber is its tendency to fray and splinter. This can lead to wastage and production delays. CNC (computer numerical control) machines have emerged as a solution to this problem. These machines use digital instructions to cut and shape fiber-reinforced materials with precision and repeatability.

CNC machining of carbon fiber is gaining popularity across several industries. In aerospace, CNC is used to produce wing spars, engine components, and other critical parts with high precision and reliability. In automotive, CNC is used to manufacture lightweight body panels, chassis components, and suspension parts that offer excellent performance and handling.

Another area where CNC machining is making a significant impact is in sports equipment. Carbon fiber is widely used in sports equipment such as tennis rackets, golf clubs, hockey sticks, and others. The use of CNC machines has made it possible to produce custom-designed parts with precise tolerances for optimal performance.

Apart from superior accuracy and repeatability, CNC machining offers other advantages for carbon fiber composites. With digital instructions, engineers can optimize designs for maximum strength and stiffness while minimizing weight and material wastage. CNC also allows for faster turnaround times and lower production costs compared to traditional manufacturing methods.

In conclusion, carbon fiber has revolutionized the world of high-performance composites, offering unparalleled strength and stiffness. CNC machining has emerged as a key tool for precision manufacturing of carbon fiber parts across several industries. With continued advances in material science and machining technology, the future looks bright for carbon fiber and CNC machining. So, if you want to get the best out of carbon fiber, CNC is the right way to go!