Description

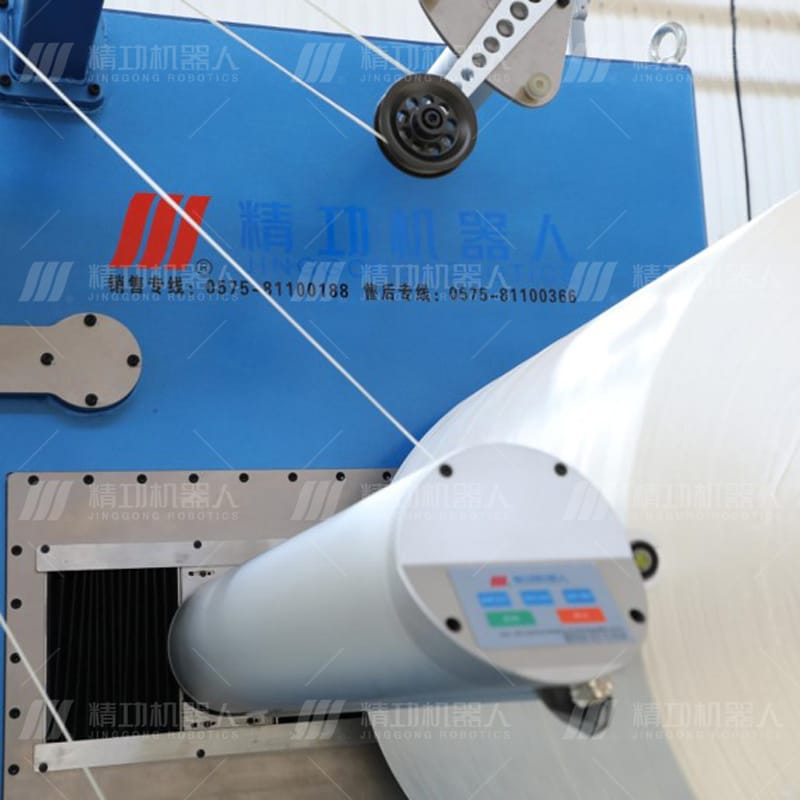

The winding machine is suitable for the winding of carbon fiber strands. The electric control and mechanical structure are designed for the winding of carbon fiber strands, which can better meet the winding of carbon fiber strands. The precise electronic winding ratio can ensure the perfect formation of the raw silk ingot and achieve precise winding.Product Video

Product Show

Advantages

FAQ

User Evaluation

The wire take-up unit fully considers the human-computer interaction, so that the operation is convenient and the wire feeding method is reasonable.The winding parameters are set accurately and reasonably to ensure that the end face of the product after winding is beautiful and has no lint.The speed of wire winding is accurately extracted from the speed of the previous wire, the winding tension is controlled reasonably, and the winding of the whole shaft is tight and full.The protection level of the unit fully considers the conductivity of carbon fiber to ensure that the equipment itself is sealed in place and has heat exchange conditions.Technological parameters such as winding tension and winding ratio need to be set to accurate values based on experience alone according to different K number of tows.The diameter of the winding reel can be read accurately, and the rotation speed of the main shaft can be followed accurately and reasonably.Tech Specs

| Model | JGRWM-2-300 | JGRWM-2-500 |

| Winding Ratio | Electronic Winding Ratio | Electronic Winding Ratio |

| Number of spindles | 2 spindles | 2 spindles |

| Rewinding diameter Max | 800mm | 940mm |

| Lead | 750mm | 810mm |

| Winding speed | 50-200m/min | 50-200m/min |

| K number | 12-50K | 12-50K |

| Inner diameter of paper tube | 133±1mm | 133±1mm |

| Paper tube length | 810mm | 920mm |

| Reel weight Max | 300kg | 500kg |