Description

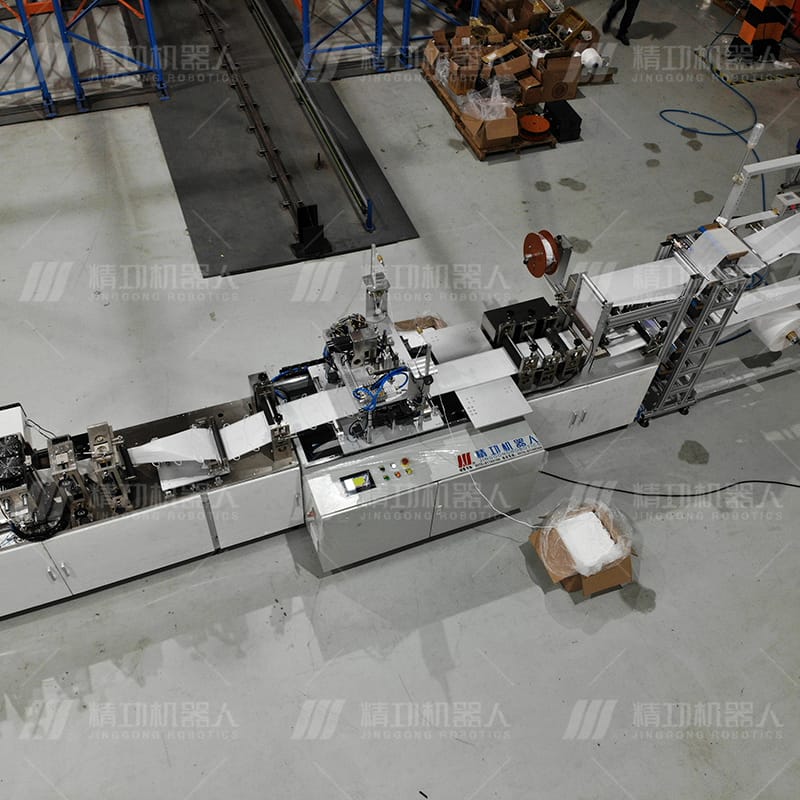

This line is used for automatic forming of folded masks: the whole roll of raw material is conveyed out through the assembly line after the process of unwinding, roller driving, nose-clip putting, nose-clip welding, (air-filled valve hole option), (printing option), ear-band welding, pair folding, edge sealing welding, cutting, finished product discharging, residual material discharging, etc. The whole process is fully automatic.Product Video

Product Show

Advantages

FAQ

Q: if a part of the equipment is damaged, can you provide the corresponding spare parts? A: before the acceptance of the equipment, our company can provide corresponding spare parts for free; If within the warranty period, we can help customers to purchase, if necessary, we can purchase for you.Q: what are the special requirements for the site? A: our company will provide customers with relevant information (such as: layout, gas consumption, power consumption, etc.) to help customers confirm.User Evaluation

Beautiful appearance, good stability and smooth mask.Tech Specs

| Product name | KN95 | ||||||||||||||||||

| Description and application area | This line is used for the automatic forming of folding mask: the whole roll of raw materials is transported out through the production line through the processes of unwinding, roller driving, nose releasing clip, welding nose clip, (gas valve hole selection), (printing selection), ear belt welding, folding, edge sealing welding, cutting, finished product blanking and surplus material blanking. The whole process is fully automatic. | ||||||||||||||||||

| Model specification / technical parameters |

| ||||||||||||||||||

| Product advantages | The automatic folding mask production line has the characteristics of stable performance, high output, low defect rate and easy operation. | ||||||||||||||||||

| Approximate lead time and time | 1 month (the specific time is mainly based on the contract) | ||||||||||||||||||

| Questions and answers | Q: if a part of the equipment is damaged, can you provide the corresponding spare parts? A: before the acceptance of the equipment, our company can provide corresponding spare parts for free; If within the warranty period, we can help customers to purchase, if necessary, we can purchase for you.Q: what are the special requirements for the site? A: our company will provide customers with relevant information (such as: layout, gas consumption, power consumption, etc.) to help customers confirm. | ||||||||||||||||||

| User evaluation | Beautiful appearance, good stability and smooth mask. |